Description

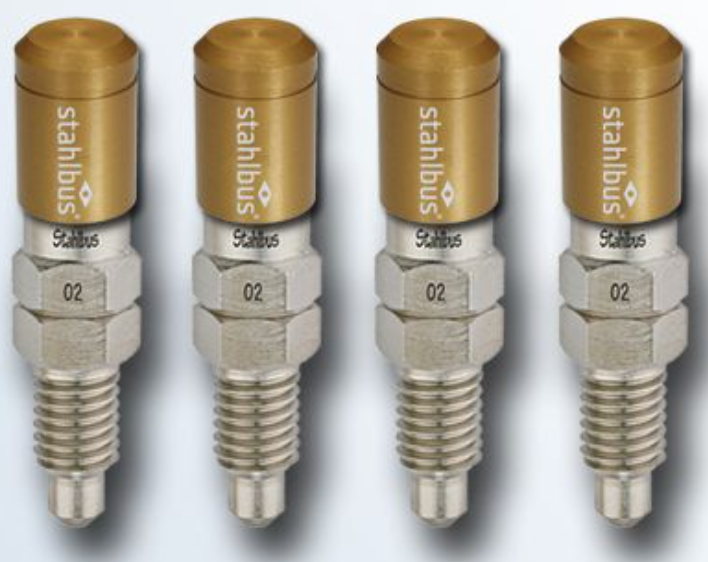

CNC precision turned part made of nickel-plated steel for substitution of the conventional bleeding nipple.

Bleeding brakes with the stahlbus® Bleeder Valve!

Bleeeding brakes

An Internet research has shown: Bleeding brakes is difficult, and sometimes it is even impossible.

We have found the reason for this problem. Our solution to it is the newly developed stahlbus® Bleeder Valve!

It solves the problem where it arises: For optimal bleeding brakes or clutches it must be completely sealed during the bleeding procedure!

No brake fluid may leak out and attack the surfaces of the calliper or painted parts. But, even much more important, no air may enter into the brake system / clutch through the thread of the bleeder valve.

Owing to the enlarged transfer ports, which are bigger than the conventional cross-holes, deposits or contaminations cannot harm this valve. Also contributing thereto are the special material and the coating.

Adding thereto is the simple one-hand operation through the integrated non-return valve. This makes the otherwise error-prone synchronous opening and closing of the conventional bleeding nipple simply superfluous. Bleeding brakes was never so easy to handle.

With the patented stahlbus® Bleeder Valve the complete bleeding process is finished within a few minutes and without any assistance.

The hydraulic brakes or clutch are easily fitted with the bleeder valve by simply substituting the old bleeding nipple with the stahlbus® Bleeder Valve. After substitution you can immedeately bleed brakes /clutches or any other hydraulic system.

The advantages of this innovative stahlbus system are obvious:

Clean: Due to absolute tightness during the entire bleeding and filling process

Quick and easy: Due to the integrated non-return valve made for single-handed operation

Safe: Due to the absolute tightness no air may ingress during the bleeding procedure

Universal: for all hydraulic systems such as brakes or clutches f.e. in cars, bikes or airplanes

Reviews

There are no reviews yet.